Custom Rotary paddle level switch Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

Paddle Level Switch Product

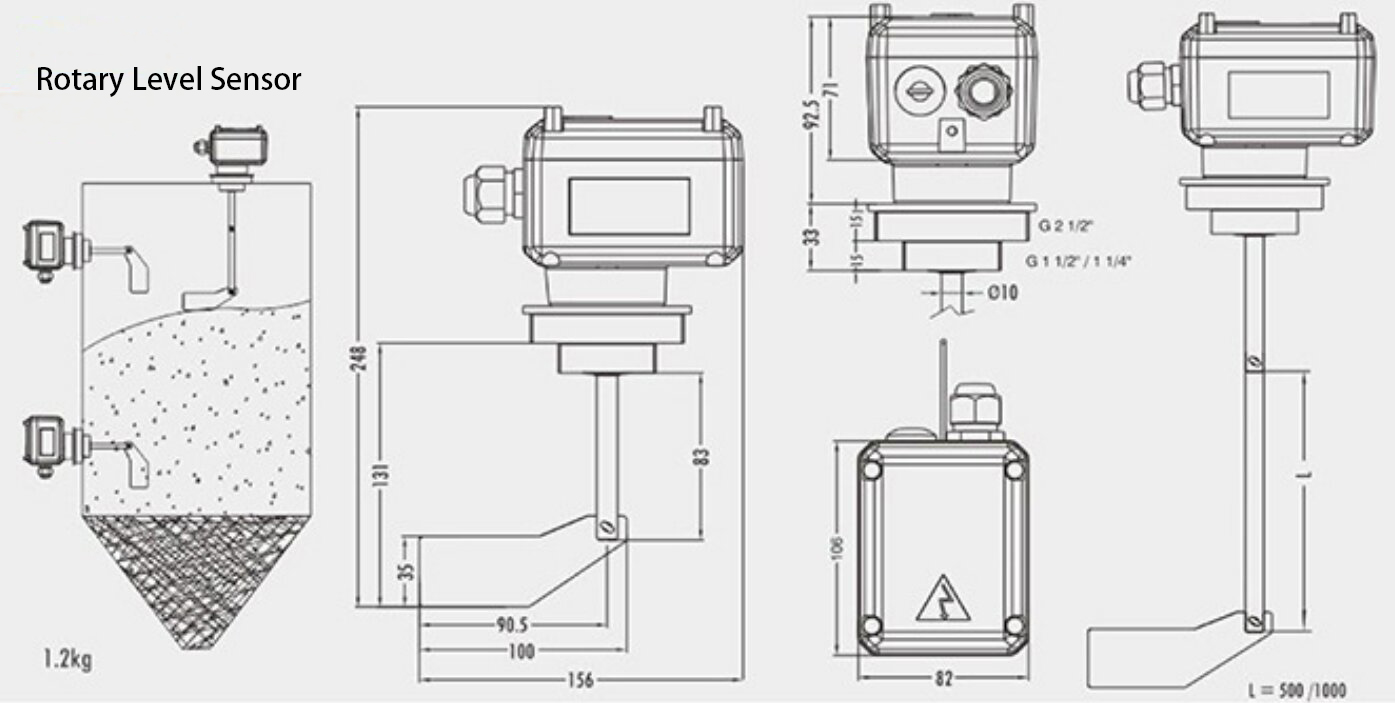

As a rotary paddle switch manufacturer, we are making our contribution to manufacturing paddle type level switch for different kinds of applications. A rotary paddle level switch is a precision-engineered device that plays a pivotal role in industrial process management by providing accurate point-level measurements. Employing a sophisticated mechanism, this switch is designed to monitor the level of bulk solids or powders in silos, hoppers, and containers.

We will provide our rotary level sensor solutions for you according to your real function and application requirements. Therefore, if you need rotating paddle level switch and rotary paddle level sensor, feel free to ask our paddle level sensor price. Here are the types of rotary level sensors. Welcome to get a free quote.

Knowledge about Rotary Paddle Type Level Switch

How does Ratary Level Switch work?

The rotating paddle level switch working principle is to operate through a rotating paddle that extends into the substance being monitored. As the material accumulates, the paddle’s rotation is impeded, triggering the switch to activate or deactivate an electrical signal. This mechanism ensures real-time awareness of material levels, preventing overflows and optimizing storage efficiency.

What are the Advantages of Rotary Paddle Sensor?

The rotary paddle level switch emerges as a quintessential sentinel in the realm of industrial process control, adorned with an array of distinct advantages that underscore its indispensability.

Robust Reliability: One of its paramount strengths lies in its unwavering reliability. The rotary paddle level switch employs a mechanical paddle to detect material levels, rendering it impervious to factors such as dust, moisture, or temperature fluctuations. This resilience ensures consistent and accurate measurements, minimizing downtime.

Versatile Adaptability: The switch’s adaptability is a testament to its engineering finesse. It seamlessly integrates into a spectrum of environments, spanning from grain silos in agriculture to complex chemical processes. This versatility simplifies implementation and guarantees operational cohesion.

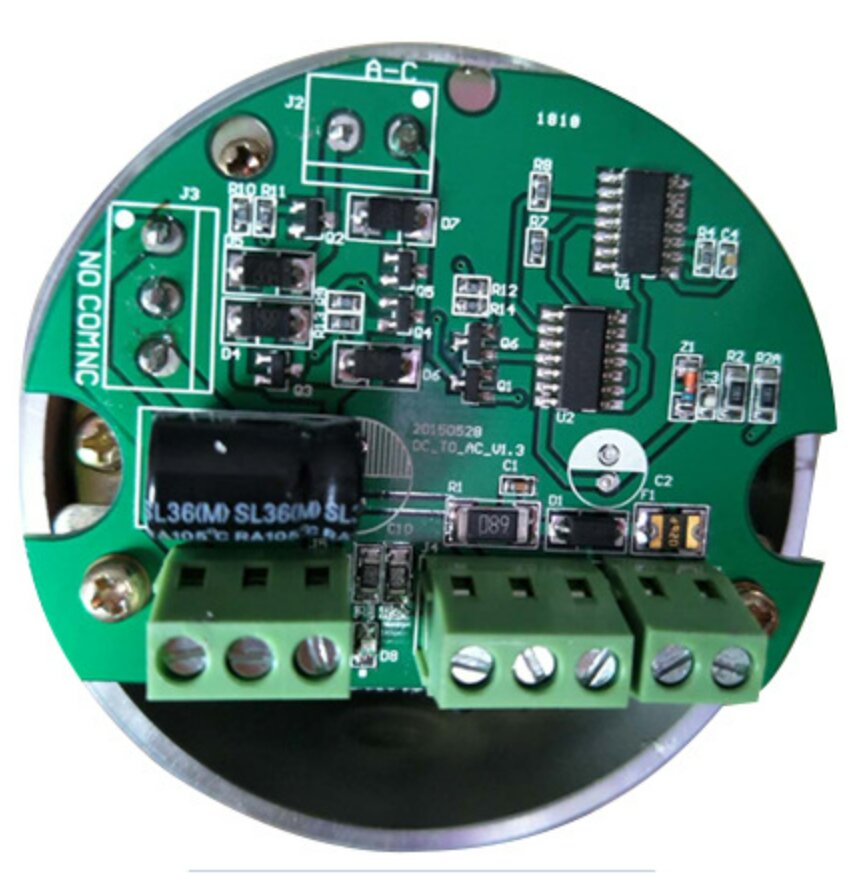

Low Maintenance Demands: Amidst the cacophony of industrial demands, the rotary paddle level switch stands as a beacon of simplicity. Its minimal moving parts and lack of intricate electronics translate into reduced maintenance needs, optimizing resource allocation.

Fail-Safe Protection: In hazardous settings, safety reigns supreme, and the rotary paddle level switch shines as a sentinel of protection. Its inherent fail-safe design triggers alarms or shutdowns upon detecting irregularities, averting potential disasters.

Cost-Effective Solution: Beyond its technical prowess, the rotary paddle level switch offers an appealing cost-effectiveness. Its robust construction, coupled with extended operational life, translates into a commendable return on investment.

As industries continue to evolve, the rotary paddle level switch maintains its venerated status, weaving a narrative of reliability, versatility, and prudence. Its advantages ripple across sectors, orchestrating a harmonious symphony of efficient material management.

What are the Applications of Rotating Paddle Switch?

In the realm of industrial instrumentation, the rotary paddle level switch stands as a stalwart sentinel, ensuring precise material management across an array of sectors. Its versatile design and meticulous engineering find purpose in diverse applications, optimizing processes and safeguarding operational integrity.

Bulk Solids Handling: The rotary paddle level switch takes the lead in granular materials handling, detecting levels in silos and hoppers with unmatched accuracy. From grains in agriculture to minerals in mining, it guarantees efficient utilization and prevents clogs or overflow.

Powder Processing: In the intricate world of powder processing, the rotary paddle level switch orchestrates control. Whether it’s pharmaceuticals, chemicals, or food production, the device maintains meticulous oversight, preventing cross-contamination and ensuring consistent output.

Material Storage: Within storage facilities, the rotary paddle level switch reigns supreme. It monitors stockpiles of raw materials, regulating replenishment and obviating shortages, thus streamlining supply chain dynamics.

Environmental Protection: Beyond industrial domains, this switch finds purpose in environmental protection. Monitoring liquid levels in wastewater treatment plants, it averts potential breaches and reinforces responsible stewardship.

Safety Assurance: Safety takes precedence in hazardous environments, and the rotary paddle level switch is a sentinel of precaution. Its steadfast vigilance prevents dangerous conditions, minimizing risks associated with combustible dust or volatile liquids.

In the grand symphony of industrial orchestration, the rotary paddle level switch is the conductor, ensuring each note is precise, each movement harmonious. Its applications extend far beyond the surface, fostering efficiency, sustainability, and reliability in every context it graces.

Why Choose Us As Your Rotating Paddle Level Sensor Manufacturer

Benefit from Your Rotary Paddle Level Switch Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

Get Your Custom Rotating Level Switch Step by Step

If you are thinking of buying rotary bin level indicator and need paddle switch level measurement solutions, you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Level Sensor Solutions? We Are Experts!

FAQ about the Rotating Paddle Type Level Switch Manufacturer

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.