Custom Float Switch Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

Float Switch Assembly Product

As a float switch supplier, we are making our contribution to manufacturing float switch sensors for different kinds of applications. A float level sensor or a float level switch is a mechanical device that measures the level of a liquid or a solid material in a container. It consists of a buoyant float attached to a stem, which moves up and down with the fluid level changes. The stem is connected to a switch or sensor that detects the position of the float and provides an electrical signal indicating the level.

We will provide magnetic water float switch solutions for you according to your real function requirement. Therefore, if you need float sensor, feel free to ask our float level sensor price. Here are the different types of the float level sensors. Welcome to get a free quote.

Knowledge about Float Switch Wholesale

What does a float level sensor do?

A float level sensor is a device designed to measure and monitor the level of liquids in tanks, reservoirs, or other containers. It serves the purpose of providing accurate information about the liquid level, enabling efficient control and management.

The primary function of a float level sensor is to detect and indicate the level of a liquid within a container. It helps in determining whether the liquid level is below, at, or above a specific threshold. The sensor relays this information to the control system or operator, enabling them to take appropriate actions based on the liquid level measurements.

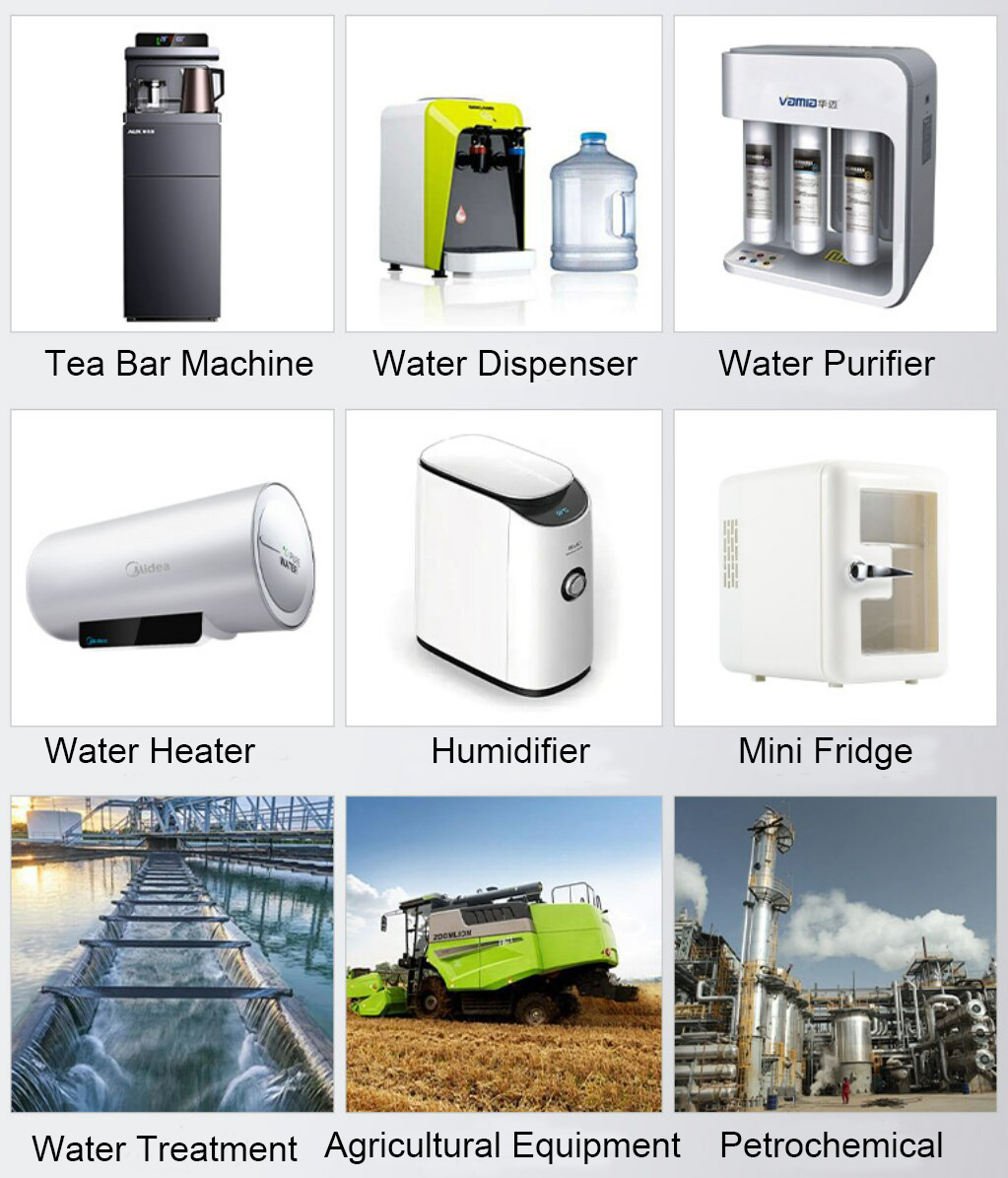

Float level sensors are widely used in various industries and applications to prevent overflow, monitor liquid levels in storage tanks, trigger pumps or alarms, and ensure optimal operation of processes that involve liquids. Water level sensor float switch find applications in a wide range of industries and sectors where precise liquid level monitoring is crucial. Some common uses include:

Industrial Tanks: Float level sensors are extensively used in industrial tanks to monitor the levels of liquids such as water, oil, chemicals, and fuels. They help prevent overflow, leakage, or equipment damage.

Process Control: They are employed in various industrial processes, such as food and beverage production, pharmaceutical manufacturing, and chemical processing, to control liquid levels and ensure optimal operation.

Pump Control: Float level sensors are utilized in pump control systems to activate or deactivate pumps based on the liquid level, preventing dry running or overflow situations.

Environmental Monitoring: They are used in environmental applications to measure water levels in rivers, lakes, and reservoirs, providing valuable data for flood forecasting, water resource management, and environmental studies.

Liquid Storage Tanks: Float switches are extensively used in tanks for water, oil, chemicals, and other liquids to prevent overflow or run-dry situations.

Sump Pump Systems: They are employed in sump pump systems to detect high water levels in basements or pits, triggering the pump to start and prevent flooding.

Industrial Processes: Float switches are utilized in industrial processes to control liquid levels, ensuring efficient operation and preventing equipment damage.

Water and Wastewater Treatment: They play a crucial role in monitoring and controlling liquid levels in water and wastewater treatment systems, preventing overflows and ensuring proper functioning in storage tanks, basins, or clarifiers.

HVAC Systems: Float switches are used in heating, ventilation, and air conditioning (HVAC) systems to regulate water levels in boilers, cooling towers, and condensate pans.

Automotive Applications: Float sensors are used in automotive applications, such as fuel tanks, to monitor the fuel level and provide accurate readings to the vehicle’s fuel gauge.

How does a float level sensor work?

The working principle of a float level sensor is based on the buoyancy of the float. As the liquid level rises or falls, the float moves accordingly. This movement is detected by the sensor, which generates an electrical signal or triggers a switch based on the predetermined level.

Float level sensors employ different types of sensing technologies, including:

Magnetic Reed Switch: This type of sensor uses a magnetic reed switch inside a sealed glass tube. When the float moves, it activates a magnet that opens or closes the reed switch, generating a signal or triggering an electrical switch.

Magnetoresistive level sensor technology: Magnetoresistive level sensor technology is an advanced method used for precise and accurate liquid level measurement in various applications. This technology leverages the principles of magnetism and resistance to provide highly reliable and responsive liquid level sensing.

Magnetostrictive Level Sensor Technology: Magnetostrictive level sensor technology is a highly accurate and reliable method used for liquid level measurement in various industrial applications. This advanced technology utilizes the principle of magnetostriction to provide precise and real-time level sensing capabilities.

Hall Effect Level Sensor Technology: Hall Effect level sensor technology is an advanced method used for accurate and contactless liquid level measurement in various industrial applications. This technology utilizes the Hall Effect principle to detect changes in magnetic fields and provide reliable level sensing capabilities.

- Mechanical Level Sensor Technology:Mechanical level sensor technology is a reliable and widely used method for liquid level measurement in various industrial applications. This technology utilizes mechanical components and principles to provide accurate and robust level sensing capabilities.

The choice of sensing technology depends on factors such as the required accuracy, the nature of the liquid, and the specific application requirements.

Why Choose Us As Your Magnetic Float Level Sensor and Switch Manufacturer

Benefit from Your Magnetic Float Sensor Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

What is the feature advantage of float level sensor?

Float level sensors offer several features that make them a preferred choice for liquid level monitoring. Here are some key characteristics:

Float Design: The sensor incorporates a buoyant float that moves up and down with the liquid level. The float is typically made of a buoyant material such as plastic or stainless steel, ensuring its accurate operation. The plastic includes PVC, PP/Polypropylene, NBR, Nylon and so on.

Precise Level Detection: Float level sensors are designed to provide precise and accurate level detection, allowing for reliable monitoring of liquid levels.

Switch or Continuous Output: Depending on the specific application requirements, float level sensors can provide either switch-type output, including single, dual or 2, and multi level, where the sensor triggers an electrical switch at a certain level to show high low liquid level, or continuous output, where the sensor provides a continuous analog or digital signal corresponding to the liquid level.

Wide Range of Materials: Float level sensors are available in various materials, including metal such as stainless steel, aluminium, brass, plastic such as NBR, PVC, PP/Polypropylene, NYLON/Polyamide(PA) and corrosion-resistant alloys with waterproof, chemical resistant and high temperature , to suit different liquids and applications.

Easy Installation: Float level sensors are typically easy to install and can be mounted vertically inside the tank or container using threaded fittings or brackets and side mounted from external tank.

Different Switch Configurations: Float level switches come in different configurations, such as side-mount or horizontal mounted(tilt mounted), top-mount, or multi-level switches. This allows flexibility in selecting the appropriate switch type based on the specific application requirements.

Adapt to different kinds of the liquids:

NC NO float switch can be mounted in different kinds of the liquids, including water such as wastewater and chemical such as oil, fuel, gasoline, coolant, diesel.

Get Your Custom Float Level Sensor Step by Step

If you are thinking of buying one kind of float level sensor, you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Level Sensor Solutions? We Are Experts!

FAQ about the Float Switch Supplier

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.