Custom RADAR Level Sensor Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

Radar Level Sensor Product

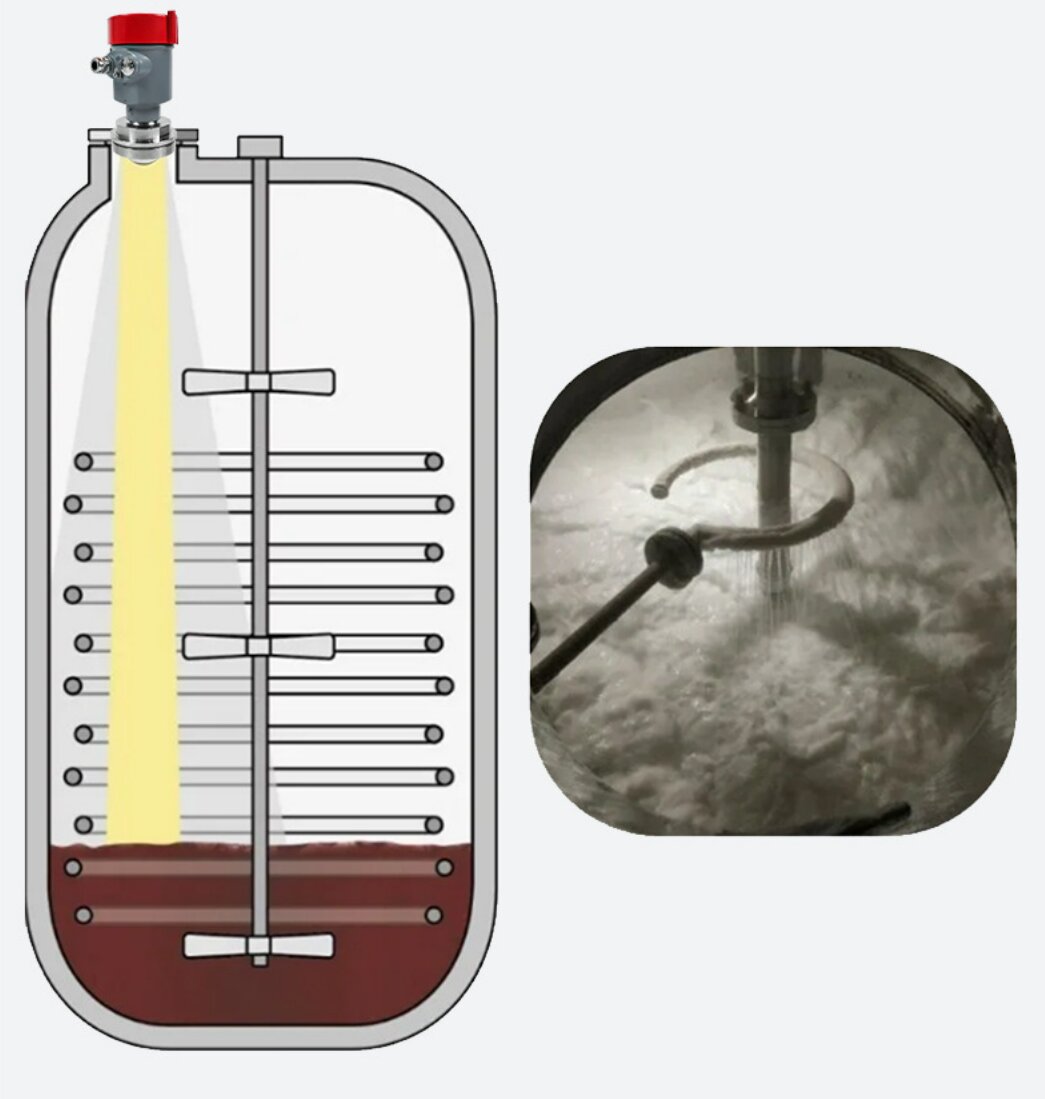

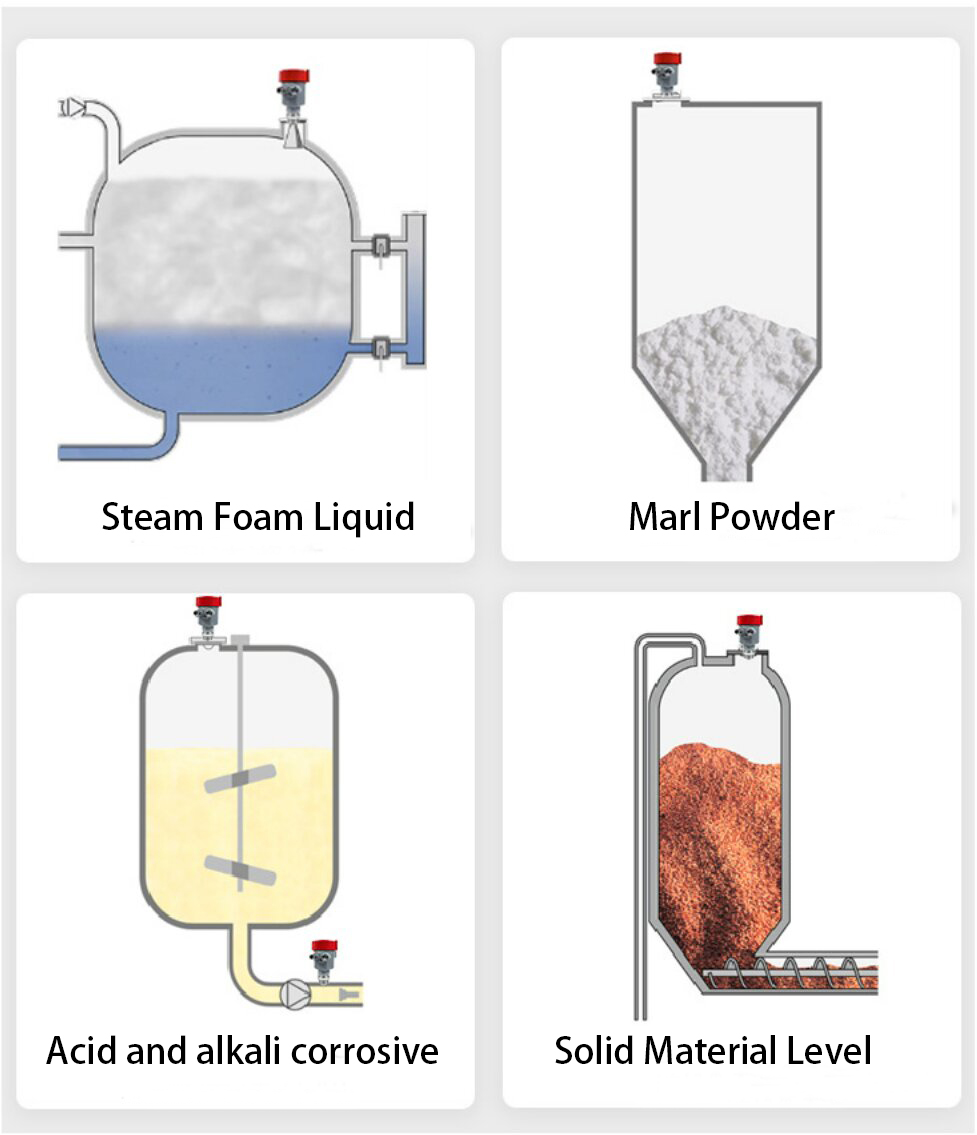

As a radar level sensor manufacturer, we are making our contribution to manufacturing radar liquid level sensor and radar type level transmitter for different kinds of applications. Radar level sensors have emerged as a game-changer in the field of liquid level measurement. These sophisticated devices utilize electromagnetic waves to provide accurate readings, making them ideal for a wide range of industries.

We will provide our radar water level sensor solutions for you according to your real function and application requirements. Therefore, if you need radar tank level sensor, feel free to ask our radar level sensor price. Here are the types of radar type water level sensors, including guided wave radar level sensor and non contact radar level sensor. Welcome to get a free quote.

Knowledge about Radar Level Transmitter

How Do Radar Level Sensors Work?

Radar level sensors operate on the principle of time-of-flight measurement. They emit high-frequency electromagnetic pulses, commonly in the microwave range, towards the liquid surface. The sensor then measures the time it takes for the signal to bounce back after hitting the surface and calculates the distance. By knowing the speed of the electromagnetic waves and the time taken for the signal to return, the sensor accurately determines the liquid’s level.

Radar Level Sensor Key Components and Technologies

Radar level sensors consist of several essential components, including the antenna, transceiver, and signal processing unit. The antenna emits the radar signals, while the transceiver handles signal reception. Advanced signal processing algorithms ensure accurate measurements even in challenging conditions, such as those involving foam or vapor.

Applications of Radar Level Sensors

Oil and Gas Industry

In the oil and gas sector, radar level sensors play a vital role in monitoring liquid levels in storage tanks, ensuring safe and efficient operations. They are particularly valuable for measuring crude oil, diesel, and other petroleum products, offering precise readings even in harsh environments.

Chemical Processing Plants

Chemical processing often involves volatile substances that require accurate level monitoring. Radar level sensors excel in this regard, enabling real-time measurements of liquids with varying viscosities and corrosive properties. This enhances the overall safety and efficiency of chemical production.

Food and Beverage Sector

From breweries to dairy processing plants, radar level sensors contribute to maintaining consistent product quality. These sensors are adept at measuring liquids such as milk, beer, and fruit juices, ensuring optimal production processes and preventing overflows.

Water Treatment Facilities

Radar level sensors play a crucial role in managing water treatment facilities by monitoring the levels of various liquids, including chemicals used for purification. The non-contact nature of these sensors prevents contamination, contributing to cleaner water production.

Advantages of Radar Level Sensors

High Accuracy and Precision

Radar level sensors boast exceptional accuracy, with deviations often measured in millimeters. This level of precision is essential for industries where even minor discrepancies can lead to significant issues.

Non-Contact Measurement

Unlike traditional methods that require sensors to come into direct contact with the liquid, radar level sensors offer non-contact measurement. This not only prevents sensor corrosion but also minimizes maintenance efforts.

Unaffected by Harsh Environments

Radar level sensors are designed to withstand challenging conditions, including extreme temperatures, pressure, and corrosive substances. This durability ensures reliable performance in diverse industrial settings.

Continuous Monitoring Capability

The continuous monitoring feature of radar level sensors provides real-time insights into liquid levels. This data enables proactive decision-making and enhances operational efficiency by preventing downtime and optimizing resource allocation.

Why Choose Us As Your Radar Level Indicator Manufacturer

Benefit from Your Radar Level Gauge Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

Get Your Custom Radar Level Meter Step by Step

If you are thinking of buying one kind of radar tank gauging system and radar water level sensor price, you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Level Sensor Solutions? We Are Experts!

FAQ about the Radar Level Switch Manufacturer

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

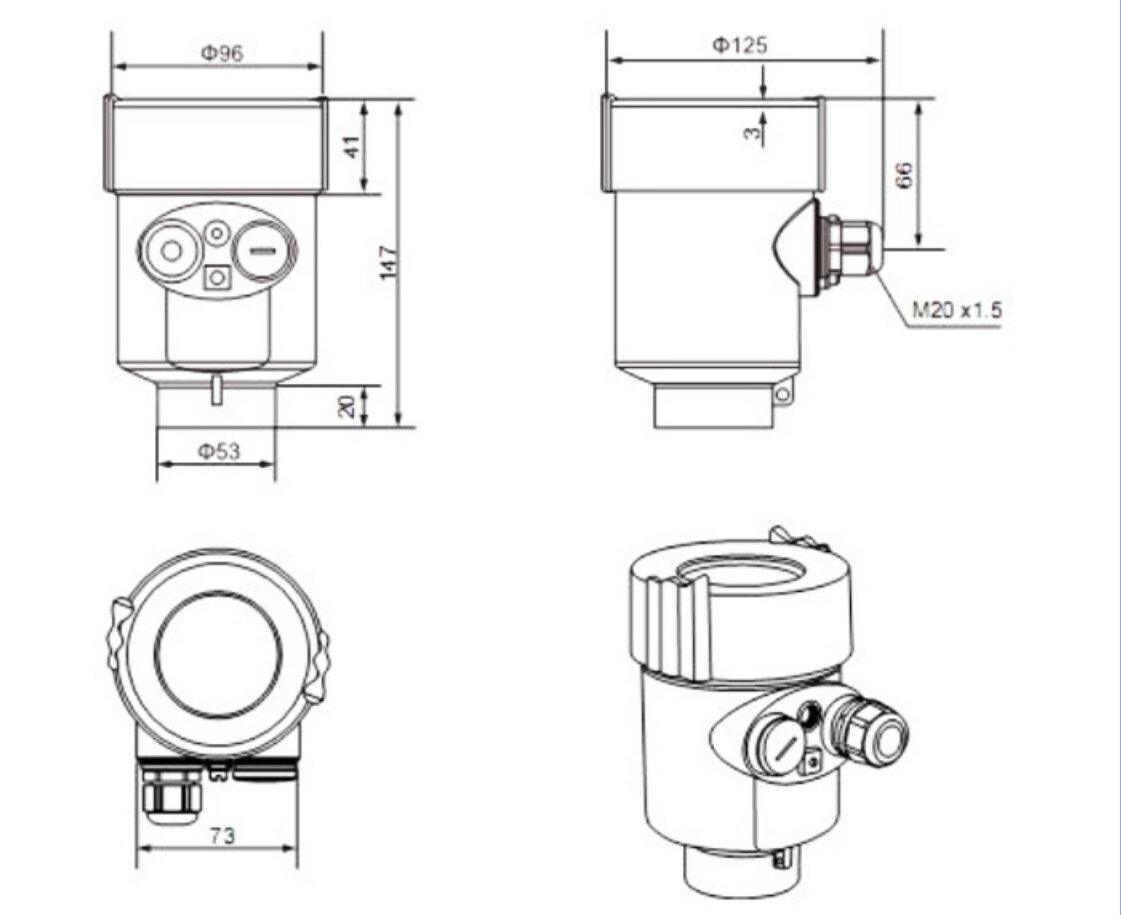

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.