Custom RF ADMITTANCE Level Sensor Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

RF Admittance Type Level Sensor Level Sensor Product

As a admittance level sensor manufacturer, we are making our contribution to manufacturing rf admittance level switch and level sensor for different kinds of applications. RF admittance level sensors are advanced instruments used to measure the level of liquids in various containers, tanks, and vessels. Unlike traditional methods that rely on float switches or pressure sensors, RF admittance sensors utilize radiofrequency technology to provide accurate and real-time liquid level data.

We will provide our RF admittance level sensor solutions for you according to your real function and application requirements. Therefore, if you need admittance level switch and admittance level sensor, feel free to ask RF admittance level sensor price. Here are the types of RF admittance level sensors. Welcome to get a free quote.

Knowledge about RF Admittance Level Switch

How does RF Admittance Level Sensor Work?

The RF admittance level switch working principle is rooted in radio frequency (RF) capacitor technology. This device employs the application of radio frequency to a probing element, allowing for a continuous analysis of the interactions within its surrounding environment. The probe, when energized, acts in conjunction with the container wall, effectively forming the two plates of a capacitor. In this configuration, the probe’s insulating material and the surrounding air serve as dielectric components. It’s important to note that all materials possess a dielectric constant greater than that of air.

When any substance other than air occupies the space, the capacitance effect is heightened, resulting in a modification of the device’s impedance. This change in capacitance subsequently triggers a discernible alteration in impedance, which is detected by the circuitry. This detected change is then compared against a predetermined reference value, set by the sensitivity adjustment of the circuit.

Radio frequency admittance, as referenced here, represents the reciprocal of electrical impedance. Comprising resistive, capacitive, and inductive components, radio frequency refers to the higher frequency range within the radio spectrum. Consequently, radio frequency admittance involves utilizing high-frequency radio waves to gauge admittance. In the operational context, the level switch’s sensor establishes an admittance value with both the container wall and the substance being measured. As the material level experiences variations, the admittance value undergoes corresponding changes. These alterations are then translated by the circuitry unit into a level signal output, thus facilitating an effective and accurate level measurement process.

What are the Advantages of RF Admittance Level Sensors?

- High Accuracy: RF admittance sensors offer exceptional accuracy, making them ideal for critical applications where precision is paramount.

- No Moving Parts: Unlike float switches, these sensors have no moving parts, minimizing wear and tear and reducing maintenance requirements.

- Wide Compatibility: RF admittance sensors can be used with a wide range of liquids, including conductive and non-conductive fluids.

- Real-time Monitoring: The sensors provide real-time data, enabling prompt decision-making and enhancing process control.

What are the Applications of RF Admittance Level Switch Sensors?

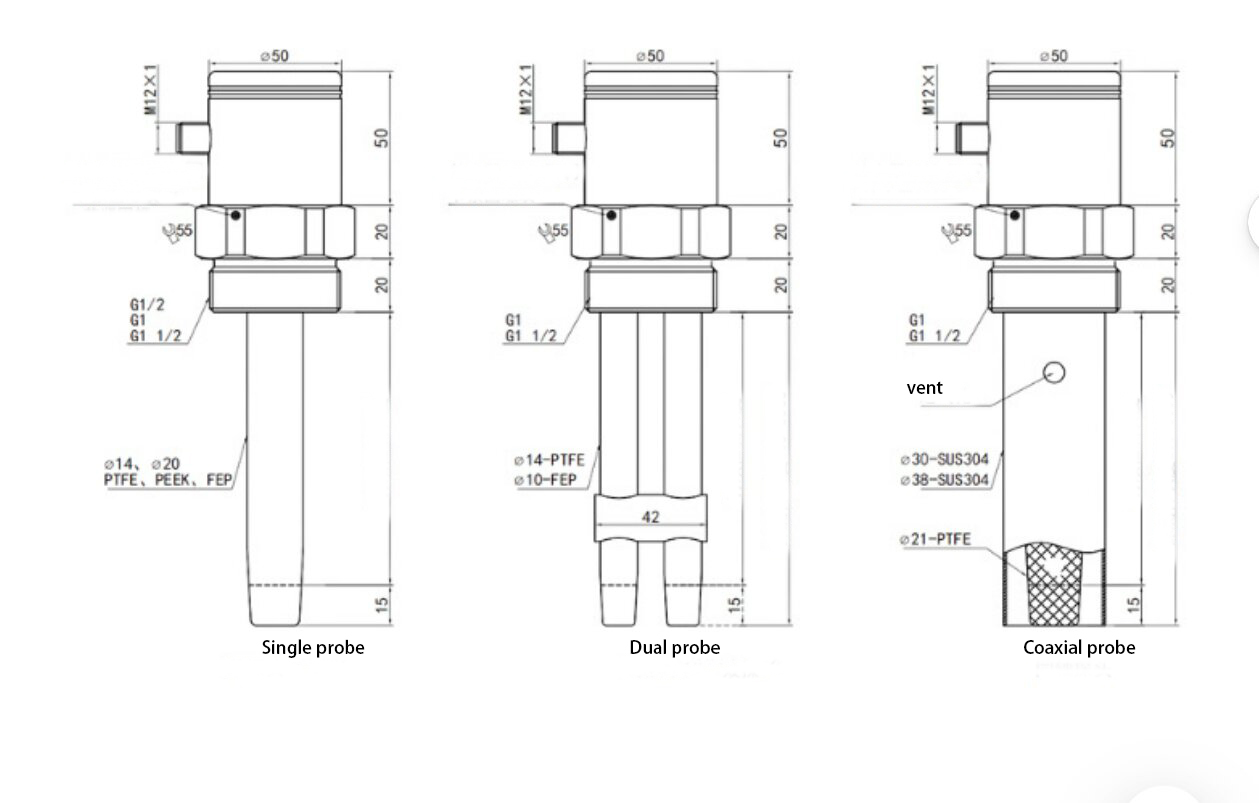

The RF admittance level switch sensor serves as a versatile solution for continuous level measurement across various industries. Designed for use in industrial and mining environments, this product finds compatibility with a wide range of applications. Comprising a circuit unit, an explosion-proof housing, and either rod or cable sensing components, the sensor offers diverse models for flexibility in installation.

The operational principle underpinning the RF admittance level sensor governs its functionality and application spectrum. The prevalence of radio frequency admittance level meters is evident in several key scenarios, including:

Chemicals, Plastics, and Films:

Ensures precise level measurement in chemical processing.

Facilitates reliable monitoring of plastic and film production processes.

Feed, Grains, and Rubber:

Optimizes level control in feed and grain silos.

Enables efficient measurement in rubber processing and manufacturing.

Pharmaceuticals and Medicines:

Contributes to the accurate handling of pharmaceutical materials.

Supports consistent measurement in medicine production.

Liquids and Wastewater:

Offers dependable liquid level monitoring in tanks and containers.

Aids in wastewater treatment and management.

Sand, Food, and Cement:

Provides effective measurement solutions for sand storage and usage.

Enhances food processing and assists in cement production.

Powders, Coatings, and Clothing:

Ensures precise measurement of powders in various industrial contexts.

Supports quality control in coatings and textile industries.

Coal and Granular Solids:

Enables efficient coal level monitoring in storage facilities.

Facilitates accurate measurement of granular solid materials.

Oil and Pulp:

Contributes to consistent oil level monitoring and management.

Assists in pulp and paper processing.

The adaptability and reliability of the RF admittance level switch sensor make it a valuable asset in a multitude of applications, enhancing efficiency, accuracy, and control across diverse industries.

Why Choose Us As Your RF Admittance Level Transmitter Manufacturer

Benefit from Your RF Admittance Type Level Switch Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

Get Your Custom Admittance Type Level Sensor Step by Step

If you are thinking of buying RF admittance level instruments and needing RF admittance level measurement solutions, you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Level Sensor Solutions? We Are Experts!

FAQ about the Admittance Level Switch Manufacturer

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.