Custom Electrode Level Sensor Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

Electrode Level Sensor Product

As a electrode level sensor manufacturer, we are making our contribution to manufacturing electrode level sensor for different kinds of applications and industries. Electrode water level sensor is also known as a “Conductivity Level Switch” , “Conductivity Level Sensors” and “Conductivity Level Switch”.

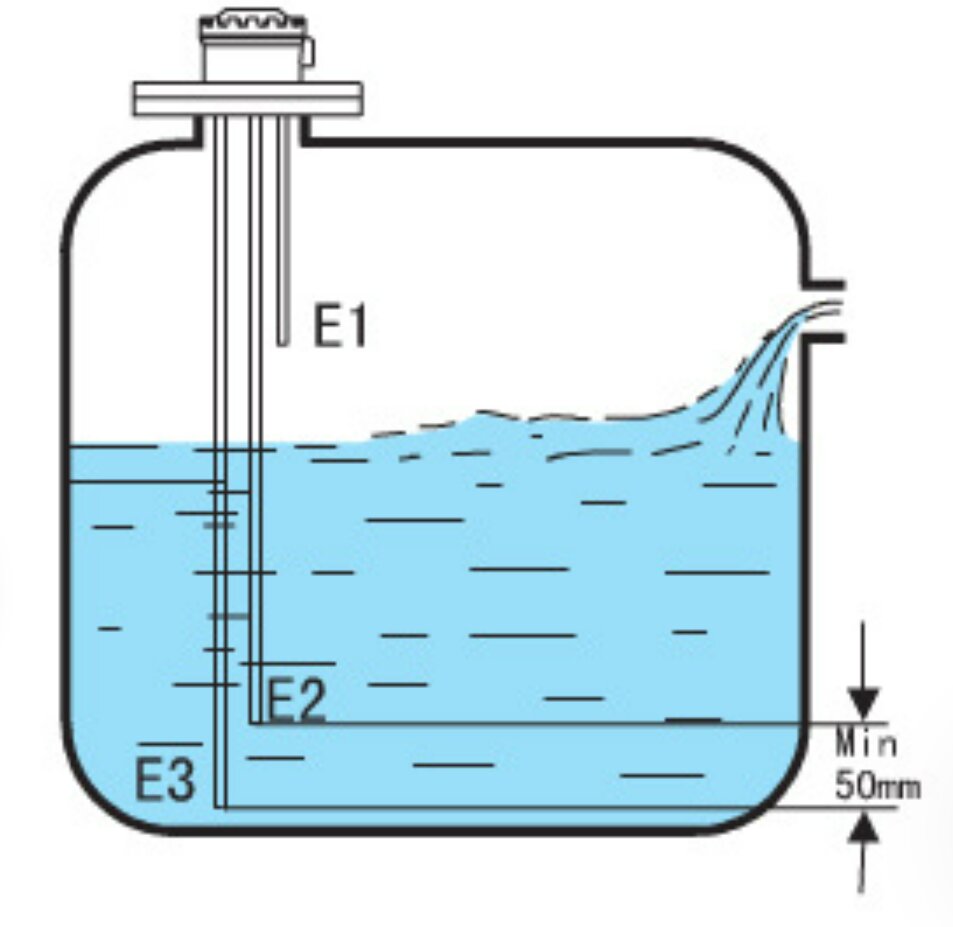

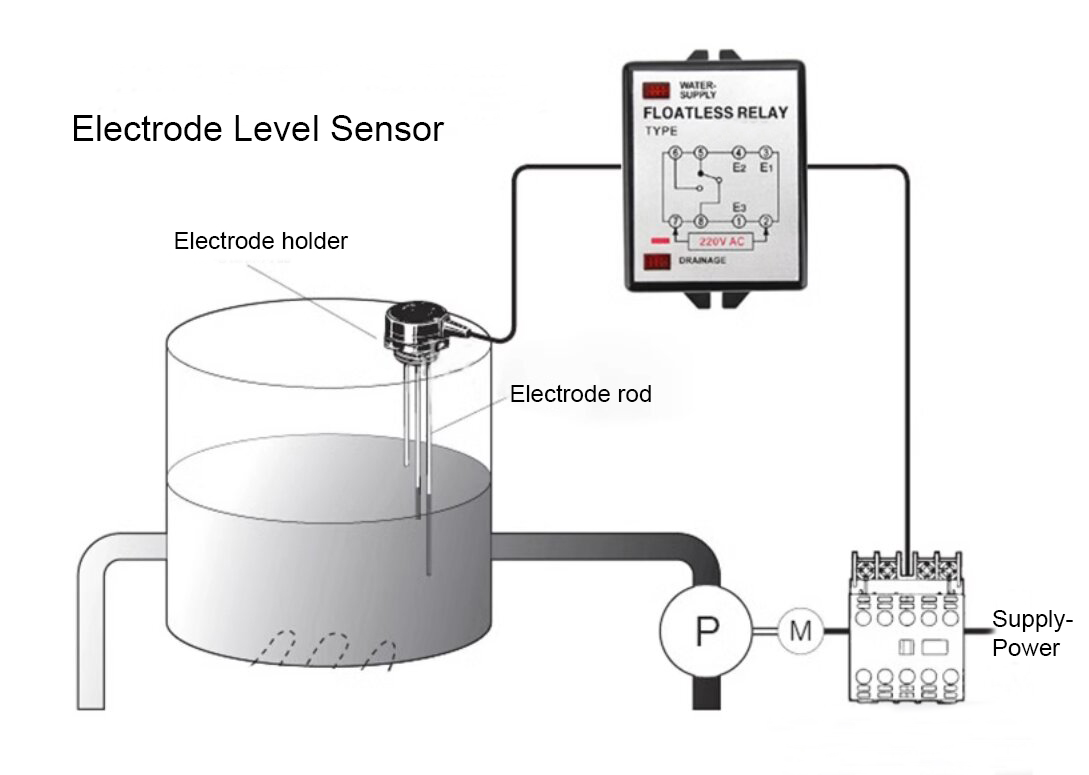

An electrode level switch is a type of sensor used to detect the presence or absence of a liquid at a specific level within a container or tank. It operates based on the principle of electrical conductivity. The switch consists of multiple electrodes that are positioned at different heights within the container. When the liquid level reaches a certain height and makes contact with the electrodes, it completes an electrical circuit, triggering the switch to either turn on or off.

The electrodes in an electrode level switch are typically made of materials that conduct electricity. When the liquid covers the electrodes, it creates a conductive path between them, allowing electrical current to flow. This change in conductivity is detected by the switch’s circuitry, which then activates the switch. Conversely, when the liquid level drops below the electrodes, the circuit is broken, deactivating the switch.

We will provide our conductivity level transmitter solutions for you according to your real function and application requirements. Therefore, if you need level sensor for conductivity level measurement, feel free to ask our floatless level switch electrode level sensor price. Here are the types of the conductivity level probe switch. Welcome to get a free quote.

Knowledge about Electrode Type Level Switch

How does Electrode Level Switch Work?

An electrode level switch operates on the principle of electrical conductivity to detect the presence or absence of a liquid at a specific level within a container or tank. Here’s how it works:

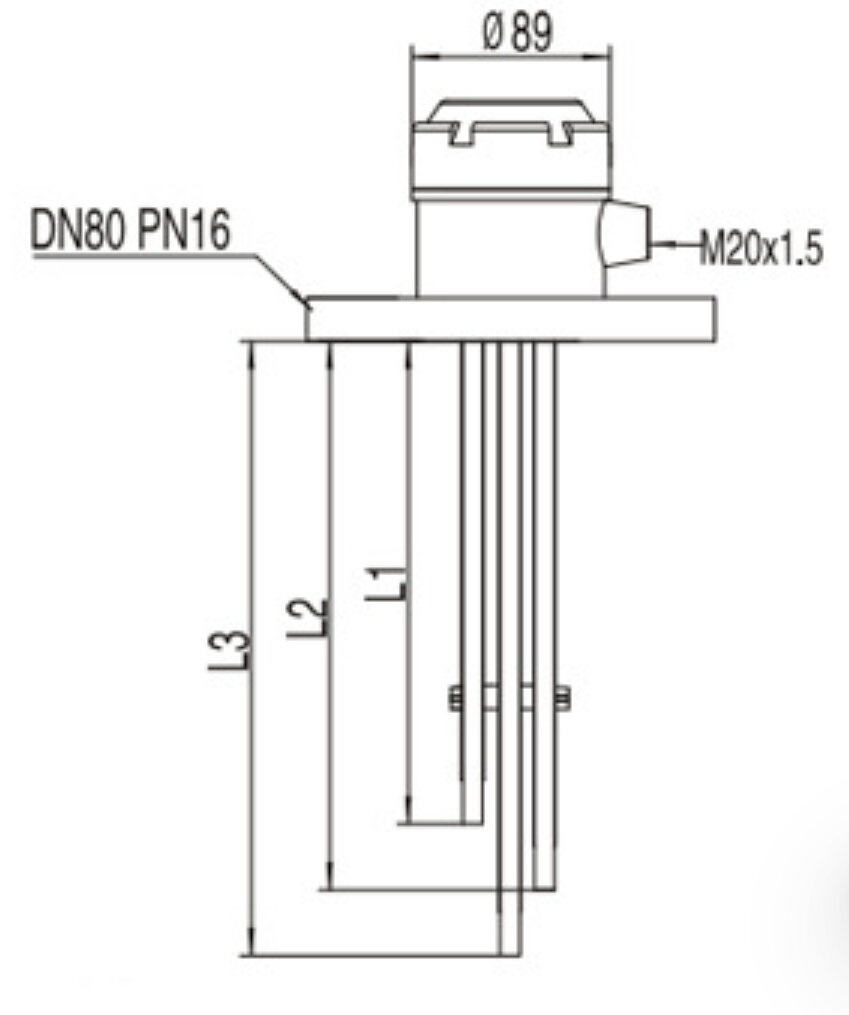

Electrode Configuration: An electrode level switch typically consists of multiple electrodes positioned vertically at different heights within the container or tank. These electrodes are made of materials that conduct electricity, such as stainless steel.

Conductivity Principle: When the container is filled with liquid, the liquid acts as a conductor, allowing electrical current to flow. The conductivity of the liquid depends on factors like its composition and impurities.

Circuit Completion: The switch’s circuit is designed so that when the liquid covers the electrodes and completes an electrical path between them, a closed circuit is formed. This allows a small electric current to flow through the electrodes and the liquid, indicating that the liquid level has reached the height of the electrodes.

Switch Activation: The closed circuit triggers the switch to activate. This activation can result in various actions, such as turning on a pump to prevent overfilling or stopping a process to prevent the liquid level from dropping too low.

Circuit Breakage: When the liquid level falls below the electrodes, the electrical path is broken, and the circuit becomes open. This change is detected by the switch’s circuitry, leading to deactivation or reversing the action initiated when the circuit was closed.

The electrode level switch’s operation is straightforward yet effective. It relies on the changes in electrical conductivity caused by the presence or absence of the liquid. This simplicity makes the switch reliable and suitable for various industrial applications where precise liquid level monitoring is essential.

In summary, an electrode level switch uses the conductivity of the liquid to complete or break an electrical circuit, triggering actions based on the liquid’s level within a container or tank.

What is the Applications of Electrode Level Sensors?

The electrode level switch finds application across various industries where accurate monitoring and control of liquid levels are crucial. Its versatility and reliability make it an essential component in several contexts. Here are some common applications of the electrode level switch:

Water Treatment Plants: In water treatment facilities, electrode level switches are used to maintain optimal water levels in reservoirs and tanks. They ensure a consistent water supply and prevent overflow, helping in efficient water management.

Chemical Processing: In chemical industries, where precise liquid levels are vital for safe and efficient operations, electrode level switches help control the filling and draining of tanks and reactors. They prevent spills, leaks, and equipment damage.

Food and Beverage Production: Electrode level switches are employed in food and beverage manufacturing to ensure consistent ingredient levels in mixing and production processes. This helps maintain product quality and efficiency.

Oil and Gas Industry: Storage tanks for oil, fuels, and chemicals rely on electrode level switches to prevent overfilling, which could lead to environmental hazards or equipment damage. They also ensure accurate inventory management.

Pharmaceutical Manufacturing: In pharmaceutical plants, where precise measurements are essential to adhere to regulatory standards, electrode level switches help maintain accurate proportions of ingredients during drug formulation.

Automotive Industry: Electrode level switches are used in automotive manufacturing to control coolant levels in radiators and reservoirs. This prevents engines from overheating and ensures optimal vehicle performance.

Wastewater Management: Municipal wastewater treatment plants use electrode level switches to manage sewage levels in collection tanks. This helps prevent sewage overflow and contamination of surrounding areas.

Power Generation: Electrode level switches play a role in monitoring water levels in steam generators and boilers, ensuring safe and efficient power plant operations.

Pulp and Paper Industry: In paper mills, electrode level switches help control pulp consistency in tanks, contributing to consistent paper quality during the production process.

Agriculture and Irrigation: Electrode level switches are utilized in irrigation systems to maintain water levels in reservoirs and control water distribution to fields, promoting efficient water use in agriculture.

Mining Operations: Mines use electrode level switches to monitor water levels in tailings ponds and water treatment systems, helping manage water resources and minimizing environmental impacts.

Beverage Dispensing: In vending machines, coffee makers, and beverage dispensers, electrode level switches ensure that water or other liquids are at the desired levels for proper functionality.

In essence, the electrode level switch’s ability to accurately monitor and control liquid levels makes it indispensable in industries where precision, safety, and efficiency are paramount. Its diverse applications highlight its importance in ensuring smooth operations across a wide range of sectors.

Benefits of Electrode Level Sensors

The electrode level switch offers several benefits across various industries due to its accurate and reliable liquid level monitoring capabilities. Here are some key advantages of using electrode level switches:

Precision and Accuracy: Electrode level switches provide highly accurate measurements of liquid levels. This precision ensures that processes and operations are controlled with minimal margin of error, leading to improved product quality and operational efficiency.

Real-Time Monitoring: These switches offer real-time monitoring of liquid levels. Operators can receive immediate alerts or notifications when the liquid reaches a certain level, enabling timely interventions and preventing potential issues.

Process Optimization: By maintaining consistent liquid levels, electrode level switches contribute to process optimization. This is crucial in industries such as chemical processing and food manufacturing, where precise ingredient proportions are essential for product quality.

Preventive Maintenance: In industries where improper liquid levels can lead to equipment damage or spills, electrode level switches act as a preventive measure. They trigger actions that prevent overfilling or running dry, reducing the risk of accidents and costly repairs.

Reduced Downtime: Timely detection of liquid level deviations through electrode level switches minimizes unplanned downtime. By addressing issues promptly, production interruptions are avoided, leading to increased operational efficiency.

Safety Enhancement: In industries dealing with hazardous materials, electrode level switches enhance safety. They prevent situations where tanks might overflow, leak, or release harmful substances, thereby protecting workers and the environment.

Versatility: Electrode level switches can be used with a wide range of liquids, including water, chemicals, oils, and more. Their adaptability makes them suitable for various industrial applications without the need for extensive modifications.

Low Maintenance: These switches have no moving parts in contact with the liquid, leading to minimal wear and tear. This design reduces maintenance requirements and associated downtime, contributing to cost savings.

Ease of Installation: Electrode level switches are relatively easy to install and integrate into existing systems. Their straightforward design ensures quick setup and minimal disruption to ongoing operations.

Remote Monitoring: Many modern electrode level switches can be integrated with remote monitoring systems, allowing operators to track liquid levels from a distance. This is particularly useful in large industrial setups.

Long Lifespan: Due to their simple design and minimal mechanical components, electrode level switches often have a long operational lifespan, resulting in a cost-effective solution over the long term.

Regulatory Compliance: In industries with strict regulations, such as pharmaceuticals and food processing, electrode level switches help ensure compliance by maintaining accurate ingredient levels and preventing deviations.

In summary, the electrode level switch’s benefits extend beyond accurate liquid level measurement. From improving operational efficiency to enhancing safety and reducing maintenance efforts, these switches play a vital role in various industries, contributing to smoother processes and better outcomes.

Why Choose Us As Your Conductivity Type Level Switch Manufacturer

Benefit from Your Electrode Floatless Level Switch Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

Get Your Custom Conductive Water Level Sensor Step by Step

If you are thinking of buying one kind of conductive probe level sensor and would like to know electrode water level sensor price, you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Conductive Type Level Sensor Solutions? We Are Experts!

FAQ about the Conductive Liquid Level Sensor Manufacturer

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.