Custom fuel Level Sensor Manufacturer in China

Advantage:

- Approved by CE & UL

- Passed ISO 9001 Quality Management System

- Stable Function and Quality Assurance

- Private Label Custom Manufacturing Ability

Get A Quote Now

Fuel Level Sensor Types Product

As a fuel level sensor manufacturer, we are making our contribution to manufacturing liquid level sensor for fuel,gas,diesel and petrol. A fuel level sensor is an electronic device designed to measure and monitor the level of fuel in a tank or container. It provides accurate information about the quantity of fuel present, allowing for better control over fuel consumption and preventing fuel-related issues such as running out of fuel or overfilling.

We will provide our diesel fuel level sensor and gauge solutions for you according to your real function and application requirement. Therefore, if you would like to know the fuel level sensor cost, feel free to ask our fuel level sensor price. Here are the types of the diesel fuel level sensor. Welcome to get a free quote.

Reed Switch Fuel Level Sensor/ Reed Type Fuel Level Sensor

Knowledge about Fuel Level Sender

What does the Fuel Level Sensor Do? How Does a Fuel Level Sensor Work?

A fuel level sensor is an essential component in vehicles and other machinery that rely on fuel. It serves the purpose of measuring and indicating the level of fuel in the fuel tank accurately. This information is crucial for drivers and operators to monitor fuel levels, plan refueling stops, and prevent fuel shortages. In this article, we will delve into the functionalities and importance of fuel level sensors.

Fuel level sensors operate using various technologies, depending on the specific type of sensor. However, the most common fuel level sensor working principle involves the use of a float connected to a variable resistor or potentiometer. The float moves with the fuel level, causing the resistance to change. This change in resistance is then converted into an electrical signal that is interpreted by the vehicle’s fuel gauge or monitoring system.

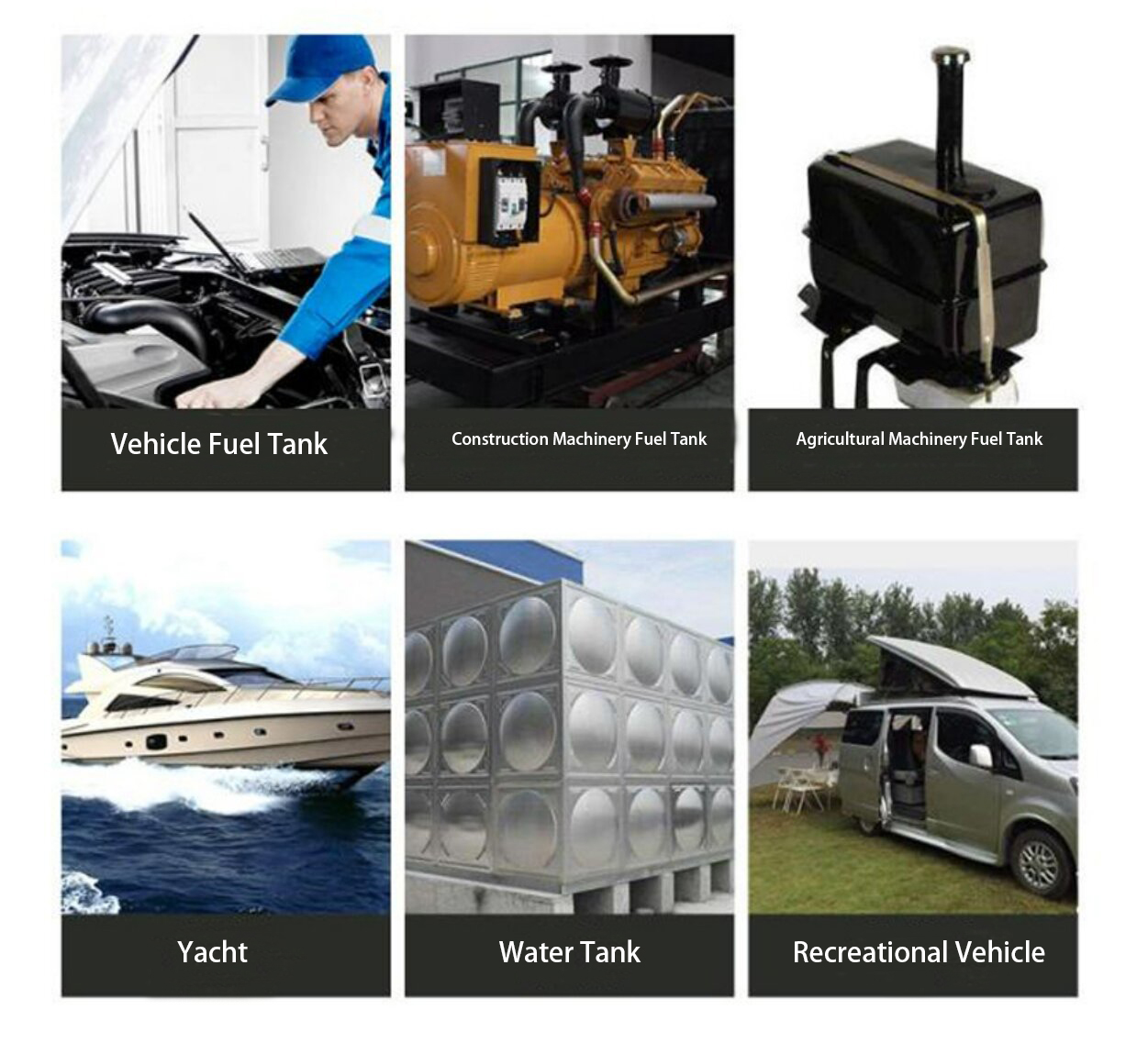

What are the Applications of Fuel Level Sensors?

Fuel level sensors find applications in various industries and settings, including:

- Automotive: Fuel level sensors are essential in vehicles for accurate fuel gauge readings, preventing fuel-related breakdowns or running out of fuel.

- Fuel Storage Tanks: In fuel storage facilities, these sensors ensure precise monitoring and prevent overfilling or leakage.

- Marine Industry: Fuel level sensors are used in boats and ships to monitor fuel levels, ensuring safe and efficient operations.

- Industrial Machinery: Many industrial machines and equipment rely on fuel level sensors to maintain optimal fuel levels and prevent disruptions.

- Aircraft Fuel Level Sensor: A fuel level sensor indicates an engine’s fuel use in real time. This can be useful to the pilot for ascertaining engine performance and flight planning.

- Fuel Level Sensor for Fuel Cell: A fuel level sensor for a fuel cell is a specialized device that measures the hydrogen level within the fuel cell. It provides real-time data regarding the fuel level, enabling precise monitoring and control of hydrogen supply. The accurate measurement of hydrogen levels is crucial for the efficient operation and longevity of fuel cells.

- Fuel Level Sensor for Diesel Generator: A fuel level sensor for a diesel generator is a specialized device that measures the fuel level within the generator’s fuel tank. It provides real-time data about the fuel quantity, enabling efficient fuel management and preventing fuel shortages. The accurate measurement of the fuel level is essential for the reliable operation of diesel generators.

Why Choose Us as Your Fuel Level Sensor Supplier

Benefit from Your Fuel Level Sensor Manufacturer

Good Manufacturing Ability & Good Quality Control

You can obtain good manufacturing ability and ISO9001 quality management system to support your level sensor quality, your machine and your brand. You can provide sketches/designs for us to design, and we will protect all the designs of every client. Then we will do our OEM & ODM for you.

Leading R&D Ability & Professional Service

You can get our leading R&D ability to design and develop the new products for your use according to your idea or the design. You can also get our professional pre service and after service to finish your project perfectly and it will give you satisfaction and make you feel at home.

Multiple Payment Method & Safe Packaging

You can make the payment by various methods, such as paypal, west union, stripe, T/T, D/P, Xtransfer, Pingpong, Payoneer, Moneygram and so on. You can be assured that you will receive the complete parcels with nice packaging. We will be responsible the goods arrive safely.

Quick Delivery & Various Transportation Solutions

You will get the cargo within 7 to 15 days on general once you give us the order and make the payment already. For our products, we usually send the goods to you by express, such as DHL,FEDEX,TNT,ARAMEX,SHUNFENG and so on. Besides, we can also provide door to door service by air. The sea, rail and truck transport is also available for you.

What are Fuel Level Sensor Advantages and Disadvantages?

Fuel Level Sensor Advantages:

Accurate Fuel Monitoring: Fuel level sensors provide precise and real-time data regarding the fuel level in tanks or containers. This enables accurate monitoring and management of fuel inventory.

Prevention of Fuel Shortages: By continuously monitoring fuel levels, fuel level sensors help prevent fuel shortages. This is crucial in applications where uninterrupted fuel supply is essential, such as backup power generators or vehicles.

Efficient Fuel Management: Fuel level sensors enable efficient fuel management by providing information on fuel consumption patterns. This allows for optimized refueling schedules, reducing fuel waste and improving operational efficiency.

Reduced Downtime: By alerting users to low fuel levels in advance, fuel level sensors help avoid unexpected equipment shutdowns or outages due to fuel depletion. This minimizes downtime and ensures uninterrupted operation.

Enhanced Safety: Maintaining appropriate fuel levels is important for safety. Fuel level sensors can prevent overfilling of tanks, which can lead to spills, fuel leakage, or other hazardous situations.

Cost Savings: Accurate fuel level monitoring allows for better control over fuel usage, leading to cost savings. It helps identify fuel inefficiencies, reduces waste, and optimizes fuel procurement.

Fuel Level Sensor Disadvantages:

Initial Cost: Fuel level sensors require an upfront investment, including the cost of the sensor itself, installation, and integration with existing fuel management systems. This initial cost can be a barrier for some users.

Maintenance and Calibration: Fuel level sensors may require periodic maintenance and calibration to ensure accurate readings. This adds to the overall cost and effort of using these sensors.

Sensor Limitations: Different types of fuel level sensors have specific limitations. For example, certain sensors may not be suitable for specific fuel types or tank materials. It’s important to choose a sensor that is compatible with the fuel and tank characteristics.

Sensor Inaccuracy: Although fuel level sensors are designed to provide accurate readings, there can be instances of sensor inaccuracies. Factors such as sensor drift, environmental conditions, or fuel properties can affect the accuracy of readings.

Sensor Failure: Like any electronic device, fuel level sensors can experience failures or malfunctions over time. This can result in inaccurate readings or complete sensor failure, requiring replacement or repairs.

Installation Challenges: Depending on the application and the complexity of the fuel system, installing fuel level sensors may pose challenges. It may require technical expertise and proper positioning to ensure optimal performance.

It’s important to weigh the advantages and disadvantages of fuel level sensors based on the specific requirements and context of the application before making a decision to implement them.

Get Your Custom Fuel Level Sensor OEM Step by Step

If you are thinking of buying fuel level sensor and fuel level sending unit , you will get the process here to finish your project!

STEP 1

Medium

Confirm Medium Type,Temperature & Pressure

STEP 2

Tank

Check Tank Type,Material & Size

STEP 3

Type & Working

Tell equipment method,level sensor types and working principle

STEP 4

Function & Output

Give required function & output

STEP 5

Prototype

2D/3D Prototype Confirmed

STEP 6

Mould

Mould Lead Time

STEP 7

Sample

Finally, we will make samples and send to customers

Need Help with Easier Fuel Level Sensor Solutions? We Are Experts!

FAQ about the Fuel Level Sensor Manufacturer

Yes, we are a leading Liquid level sensor manufacturer, supplier and factory in china.

Of course, we are professional in OEM/ODM projects and we protect all the designs of every client, we will sign NDA to be ensure that we won’t send your artwork to any other clients and won’t sell your OEM items to anyone else. Any questions please send us your inquiry.

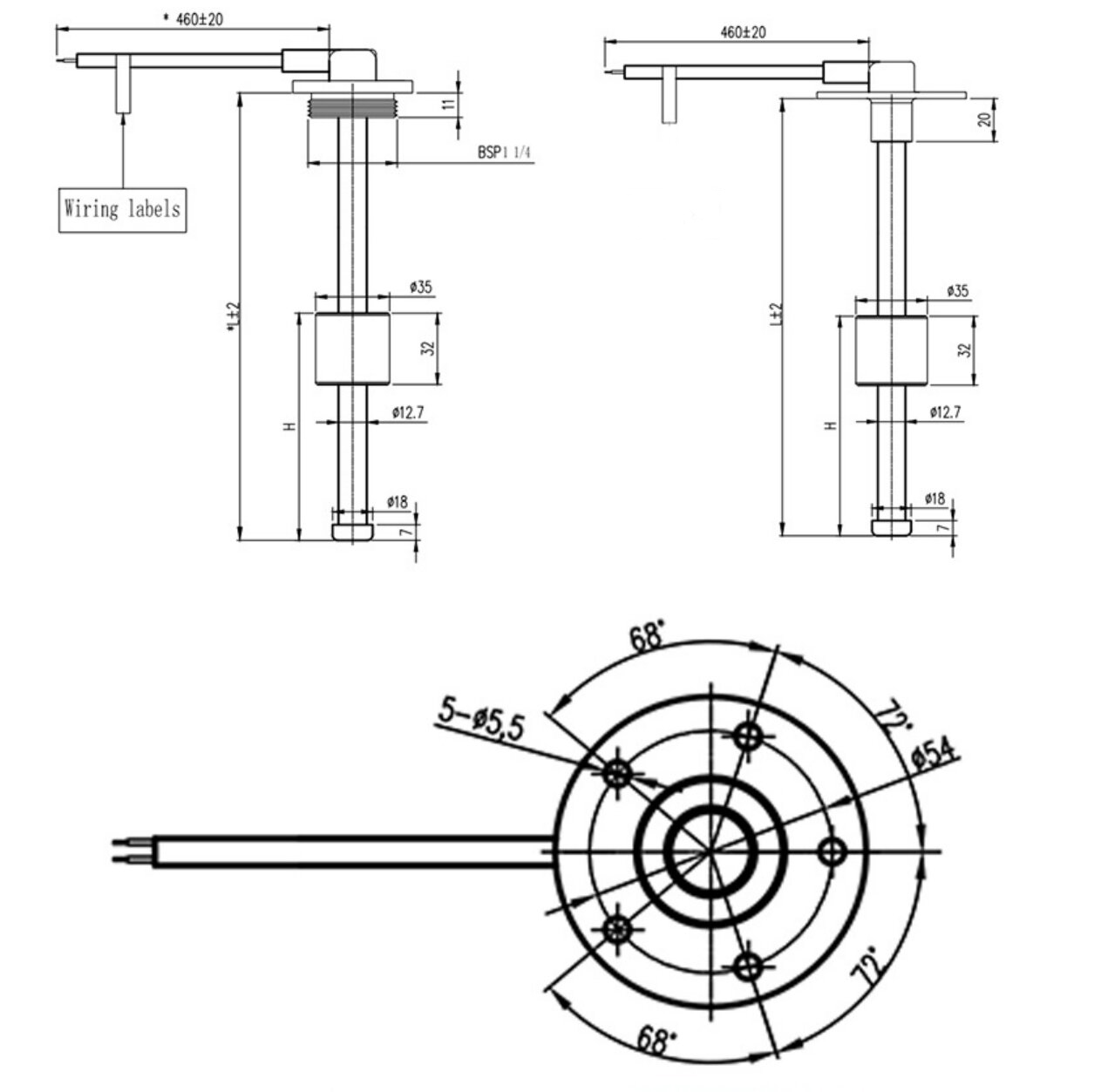

Yes, we provide PDF technical drawing by CAD on general. However, if you need 3D drawing to match with your 3D drawing to confirm if our developed product is suitable, we can provide 3D drawings by Solidwork and so on.

Yes, we have our R&D teams, hardware and software, lab equipment and instruments to design and develop new product for every customer.

Yes, we have ISO9001 quality management system and IATF 16949 quality management system to control our water level sensor quality. We also have CE and UL certification to fulfill European and North American markets.

Aether level sensor MOQ is 1 pc. We are willing to give samples for our every customer if you are interested in establishing good and long relationship with us. The samples lead time is short and it is usually within 3 to 5 days.

We have pvc pipe, bubble bag, foam, custom carton,blister box to make our packaging safe and provide affordable dhl, tnt, fedex for every customer. If you want door to door service, we can give DDP trade term.

Our delivery time is 7 to 15 days on general and payment terms can be T/T, D/P,L/C and so on.